Engineering

Challenges Welcome

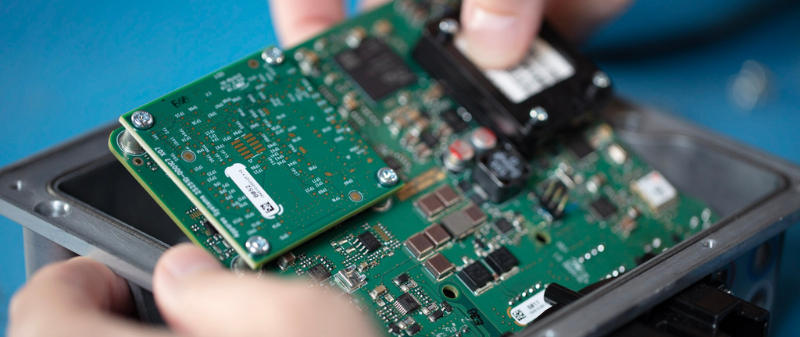

Whether you need an innovative solution to a specific problem, or you have a design that needs to be refined, our experienced engineering team is up to the task. From concept to completion, our engineers work in tandem with our manufacturing team to maximize production efficiency and ensure the final product meets all specifications and quality standards. Our products are used globally, and we have extensive experience developing products that meet specific industry and governmental regulations for diverse markets around the world.

Experienced in Every Discipline of Design

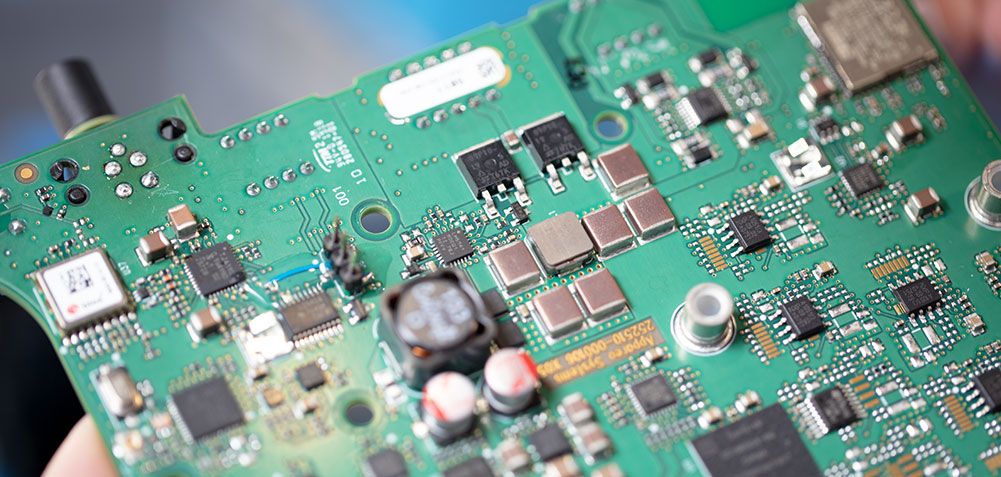

Our dedicated teams of electrical, mechanical, and software engineers work together during every step of the product development process to ensure our designs perform as well in practice as they do on paper. We specialize in a variety of design areas required for rugged electronics including radios/wireless, telematics, FPGAs (VHDL/Verilog), embedded software, optical and acoustic sensors, and enclosures for all environmental conditions. We know what it takes to design products that can withstand extreme environmental conditions.

Experienced in Every Discipline of Design

Our dedicated teams of electrical, mechanical, and software engineers work together during every step of the product development process to ensure our designs perform as well in practice as they do on paper. We specialize in a variety of design areas required for rugged electronics including radios/wireless, telematics, FPGAs (VHDL/Verilog), embedded software, optical and acoustic sensors, and enclosures for all environmental conditions. We know what it takes to design products that can withstand extreme environmental conditions.

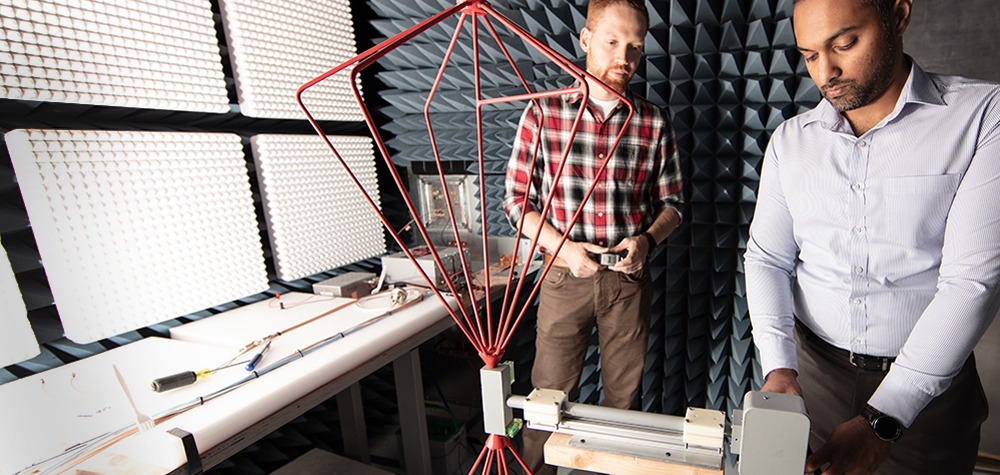

Product Test Engineering

Appareo has extensive design and test laboratories to ensure our products perform as promised. Throughout the development process our engineers utilize our wide variety of electronics and RF test equipment including network analyzers, spectrum analyzers, GSP simulators and waveform generators. We also have engineering labs dedicated to prototyping and 3D printing.

Our test facility is fully equipped with semi-anechoic chambers for EMC and RF (wireless), environmental, vibration, and shock testing. It also includes equipment for testing electrical transients and other energy measurements. In addition to extensive field testing, our experienced team can develop custom testing environments to ensure our products uphold system performance, software, and environmental requirements. All of our tests are performed according to internationally recognized standards governed by RTCA, SAE, ISO, and others. For certified avionics, we can test and certify most DO-160 test levels in-house.

PDF Download: Appareo Test Engineering Overview

Artificial Intelligence for Real World Applications

With the ever-changing capabilities of modern machines, quantifiers like horse power and man hours are starting to sound nostalgic. We’re focused on the future where the potential for increased precision and productivity is almost immeasurable. We specialize in artificial intelligence for real-world applications. From delivering data to improving automation, we’re constantly pushing ourselves to find innovative solutions to challenging problems.

Learn more about our Aviation Speech Recognition System.

Artificial Intelligence for Real World Applications

With the ever-changing capabilities of modern machines, quantifiers like horse power and man hours are starting to sound nostalgic. We’re focused on the future where the potential for increased precision and productivity is almost immeasurable. We specialize in artificial intelligence for real-world applications. From delivering data to improving automation, we’re constantly pushing ourselves to find innovative solutions to challenging problems.

Learn more about our Aviation Speech Recognition System.

Capabilities for Communications and Connectivity

From custom sensors to complex telematic devices, we develop rugged electronics for industrial and commercial applications. We understand the intricacies of incorporating cellular, Bluetooth, WiFi, GPS and Iridium satellite technologies into our products for advanced communication and connectivity capabilities.

Learn more about our highly capable Telematic Control Units.